g., accumulating many centrifuge loads from a single crystallization batch) or combining fractions from quite a few batches for additional processing is considered to be Section of the creation method and is not considered to be Mixing.

Residual materials is often carried in excess of into successive batches of a similar intermediate or API if there is suitable control. Examples consist of residue adhering to the wall of a micronizer, residual layer of moist crystals remaining in a centrifuge bowl after discharge, and incomplete discharge of fluids or crystals from the processing vessel upon transfer of the fabric to the next move in the method.

procedures for production of little molecules and for procedures employing recombinant and nonrecombinant organisms for production of proteins and/or polypeptides are a similar, Even though the diploma of Manage will differ.

Introducing an intermediate or API, like one particular that does not conform to benchmarks or requirements, again into the method and reprocessing by repeating a crystallization phase or other proper chemical or Bodily manipulation actions (e.

Procedure investigation and development, such as route and procedure layout for each scientific enhancement and professional use

An entire description of the solutions and materials, which include dilution of cleaning brokers utilised to scrub gear

True yields should be in contrast with expected yields at selected ways while in the manufacturing system. Anticipated yields with proper ranges ought to be recognized according to previous laboratory, pilot scale, or manufacturing data.

Procedures for the usage of services should be sure that materials are handled within a way that minimizes click here the risk of contamination and cross-contamination.

Consultants advising over the manufacture and control of intermediates or APIs ought to have sufficient instruction, instruction, and encounter, or any mix thereof, to advise on the subject for which they are retained.

In-course of action controls as well as their acceptance standards must be defined according to the information attained in the developmental phase or from historical information.

Any substances associated with the Procedure of kit, such as lubricants, heating fluids or coolants, should not Make contact with intermediates or APIs so as to change the caliber of APIs or intermediates outside of the official or other proven specs.

Materials must be saved beneath conditions and for any period of time which have no adverse impact on their quality, and will normally be managed so that the oldest stock is utilized 1st.

In advance of a decision is taken to rework batches that do not conform to recognized requirements or specs, an investigation into The key reason why for nonconformance ought to be carried out.

Course of action validation should ensure which the impurity profile for each API is within the limits specified. The impurity profile must be comparable to, or much better than, historic information and, where by applicable, the profile determined through process advancement or for batches employed for pivotal medical and toxicological studies.

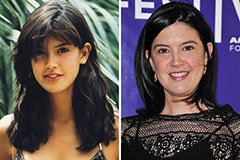

Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!